- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

FiltersFilter & Sort

4" x 6" Direct Thermal Labels - 24 Rolls

$259.95Unit price /Unavailable2 1/4" x 50' Thermal Paper Rolls - 100 Rolls

$25.00$54.95Unit price /Unavailable- $24.95Unit price /Unavailable

3 1/8" x 220' Thermal Paper Rolls - 50 Rolls

$74.95Unit price /Unavailable

Thermal Paper Collection

Patek Packaging understands the need for efficiency and cost-effectiveness, so we offer a comprehensive collection of thermal paper rolls designed to meet your diverse printing or labelling demands.

As we introduce our high-quality thermal papers, we will also give you valuable insights about their material composition, uses, and selection standards. You can expect to find the perfect solution for your business needs.

About the Product

Thermal paper, also known as heat-sensitive paper, is a unique type of paper coated with a special layer that reacts to heat. This coating undergoes a chemical reaction when exposed to heat from a thermal printer head. This reaction darkens the specific areas of the coating, creating the printed image and eliminating the need for traditional ink or toner.

Compositions

Base Paper

The base paper is the foundation layer for thermal paper, usually crafted from wood pulp. It's coated with a precoat to create a smooth printing surface. Alternatively, synthetic thermal stocks can be used. This layer is vital for durability, heat insulation, image clarity, and overall performance, laying the groundwork for dependable, top-notch prints.

Precoat Layer

Positioned between the base paper and thermal coating, its main role is to create a smooth surface for even thermal coating applications. This step is crucial for producing clear images when the paper reacts to heat. The precoat layer also enhances the adhesion of the thermal coating, improving print quality and preserving the paper's longevity.

Thermal Coat

The thermal coat is the key layer in thermal rolls, causing special heat-sensitive reactions. This coat is chemically designed to change colour when exposed to heat. When the paper passes through a thermal printer, the printer's heat triggers the chemicals in this layer, creating text or images. In this coating, it is made up of the following:

|

Leuco Dyes |

These colourless chemicals change colour when exposed to heat. Different types of leuco dyes offer varying shades and sensitivities for diverse printing uses. |

|

Sensitisers |

Sensitisers adjust the paper's heat sensitivity to match the designated printer's specific temperature range, ensuring compatibility. |

|

Stabilisers |

Stabilizers preserve the print's quality over time, preventing rapid fading and extending the lifespan of the printed image. |

|

Developers |

These chemicals activate leuco dyes upon heating, producing the clear and visible print often found on items such as receipts. |

Features

This paper is mainly used for thermal printing. So, it's important that it maintains good printing quality and image stability, in addition to typical paper features like weight and thickness. It should also be compatible with traditional printing methods like Flexo or Offset.

General Properties:

- Basic properties include grammage (weight), thickness, and moisture content.

- Strength properties encompass tensile strength (resistance to pulling), tearing strength (resistance to ripping), and elongation (ability to stretch).

- Surface properties include brightness, opacity (level of see-through), whiteness, smoothness/roughness, and surface strength (resistance to scratches and scuffs).

- Absorption properties include water absorption, oil absorption, and printing ink absorption.

Unique Properties:

- Image stability refers to how long a thermal print will remain readable under proper storage conditions.

- Density is an optical value measured from the thermally printed image, indicating the darkness and sharpness of the print.

- Static sensitivity determines the temperature at which the thermal image starts to form. Lower static sensitivity means the image forms at higher temperatures, while higher static sensitivity indicates image formation at lower temperatures.

- Dynamic sensitivity signifies the speed and energy required for optimal printing. Higher dynamic sensitivity translates to better print quality.

Benefits

- Fast Printing: Thermal printing is significantly faster than traditional ink or toner-based printing methods, ideal for high-volume applications.

- Cost-Effective: Eliminates the need for additional consumables like ink cartridges, making it a budget-friendly option.

- Compact Design: Thermal printers are generally smaller and lighter than their ink-based counterparts, saving valuable space in your workspace.

- Environmentally Friendly: While not always the case, some options are recyclable under specific conditions.

Common Applications

- Receipts: Widely used for printing receipts in retail stores, restaurants, and hospitality settings.

- Labels: Thermal labels are used for various applications, including product labelling, shipping labels, and barcodes.

- Tickets: Thermal printers are commonly used for printing event tickets, boarding passes, and lottery tickets.

- Medical Records: Used for printing medical records, although its use in healthcare settings is declining due to concerns about image longevity.

Also, this type of paper finds applications in credit card terminals, cinema tickets, play tickets, hospital records, ATM receipts, thermal photo printers, price tags, shipping labels, barcode labels, and various other uses.

Choosing the Right Paper For Your Business

Selecting the appropriate paper is crucial for achieving a good printing performance and ensuring the longevity of your printed information. Here are some key factors to consider:

- Printer Compatibility: Ensure the paper roll's size and core diameter are compatible with your specific thermal printer model.

- Printing Application: The type of application will influence your choice. For instance, receipts may require a lighter basis weight paper, while shipping labels benefit from a thicker and more durable option.

- Basis Weight: The paper's thickness is measured in grams per square meter (gsm). Higher basis weight usually indicates thicker paper, offering improved durability and resistance to tearing.

- Top Coating: Some papers feature a top coating that enhances print quality, protects against scratches and smudges, and extends the lifespan of the printed image.

- Environmental Factors: Consider factors like temperature, humidity, and light exposure in your printing environment. Some paper types are more susceptible to fading or smudging under specific conditions.

- Shelf Life: This paper has a limited shelf life, and the printed image can fade over time. Choose paper with an appropriate shelf life based on your usage patterns.

Our Product Selection Guide

Patek Packaging offers different thermal roll options, which vary by size and quantity.

|

Product |

Colour |

Size |

Case Pack |

Price |

|

Direct Thermal Labels |

White |

4x6” |

24 rolls |

$259.95 |

|

Thermal Paper Rolls |

White |

2.25x50” |

100 rolls (carton) |

$54.95 |

|

Thermal Paper Rolls |

White |

3.125x 220” |

50 rolls |

$74.95 |

|

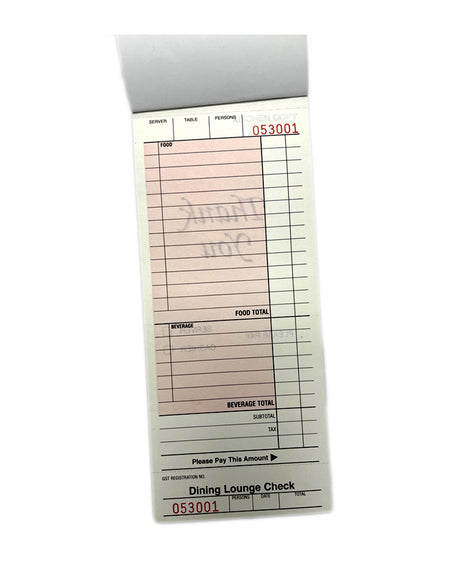

Guest Check Book |

- |

8.5x3.5x5” |

10 pack |

$24.95 |

Thermal Paper Rolls at Patek Packaging

Experience the convenience and efficiency of Patek Packaging's Thermal Paper Collection today. Explore our range of products and streamline your printing and labelling processes for improved productivity and customer satisfaction.

Frequently Asked Questions

When did thermal paper technology started?

This paper technology dates back to the early 1950s and has progressed alongside printing advancements. They cater to various needs, including receipt rolls, patient wristbands, restaurant menus, tags, labels, and more. These papers come in different types tailored to specific application demands, offering features like fade resistance, grease/water resistance, print quality, and cost-effectiveness.

Is thermal paper toxic?

This type of paper includes Bisphenol A (BPA) in its heat-sensitive layer, which may have health implications due to its endocrine-disrupting properties. But, the amount transferred to the skin is small, and the health risks are still debated.

Some manufacturers now offer BPA-free thermal paper, using alternatives like Bisphenol S (BPS) to address these concerns. Although BPS is deemed safer, its long-term effects are still being studied. To reduce potential exposure, it's recommended to wash hands after handling receipts.

How long do these papers last?

- Shelf Life: Store below 77 degrees Fahrenheit in a dark, low-humidity environment can last around three years from its manufacturing date.

- Image Life: Once printed, images can endure for at least seven years when stored at 77 degrees Fahrenheit in a dark, low-humidity setting.

- Fade Resistance: The combination of thermal paper's dye and co-reactant makes it susceptible to ultraviolet (UV) light.

- Exposure to UV light, such as sunlight, can compromise the printed image and may lead to discoloration of the paper itself.

Is thermal paper recyclable?

They cannot be recycled in traditional paper recycling processes due to its chemical coating. The coating contains Bisphenol A (BPA) or similar chemicals, which can contaminate the recycled paper stream. So, if available, they should be disposed of in regular waste streams or through specialized recycling programs.